Tested to Failure

Jason Morrison, ITS, Parking & Public Transport Market Manager, explains how the Daktronics Reliability Lab is important for equipment like dynamic ITS signage. This interview first appeared in ITS International for the 2023 ITS America Conference & Expo.

5/15/2023

Categories: Transportation

What goes on in the Product Reliability Lab?

We use our on-site Reliability Lab to rigorously test components and cabinets. The challenges of outdoor environments test the performance limits of LED display technology. That’s why we test our products to complete failure. It provides our engineers with a detailed portrait of a product’s vulnerable areas. We use this data to design and improve our products so that you get an incredibly tough and reliable display.

What sorts of weather conditions can you simulate?

Our Reliability Lab systems and testing equipment includes some like those used by the automobile and aerospace industries.

Our environmental chamber simulates operating environments with extreme temperatures or humidity levels.

Our salt fog chamber simulates corrosive effects of coastal precipitation.

Our HALT (highly accelerated life test) chamber combines temperature shock and vibration forces to stress products structurally, electrically, and thermally to uncover design weaknesses.

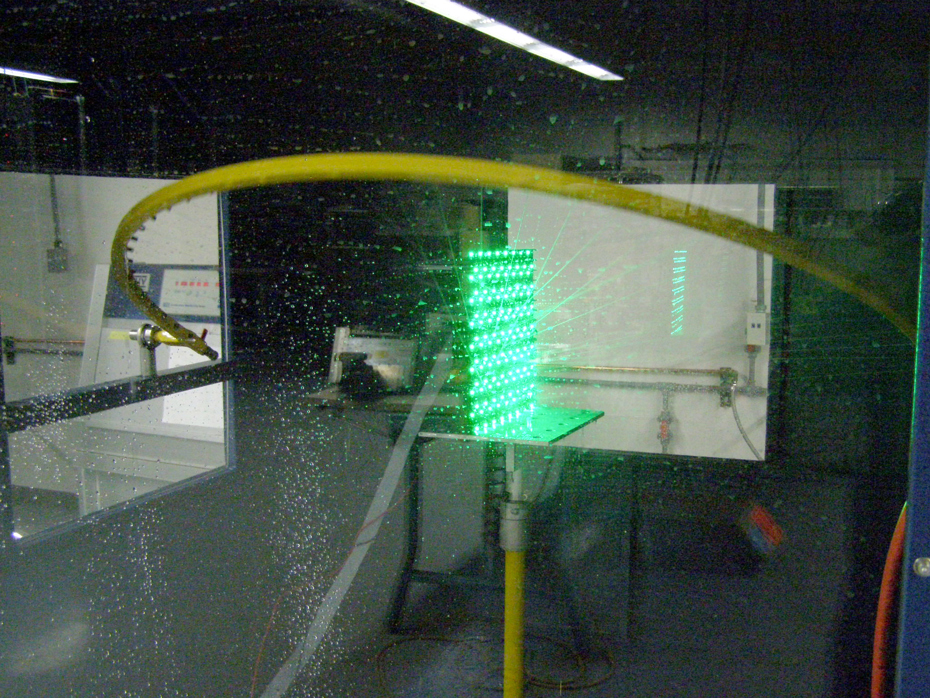

Our spray test chamber tests water protection of an enclosure or cabinet.

And those are just some of the tests. We put every component through a staggering 63 steps.

Measuring performance through all stages of lifecycle is critical for good design choices. Our products are designed to withstand the harsh weather environments that ITS dynamic message signage experiences every day. The results are superior and reliable products. Reliability is key for communicating messages in real-time to keep travelers safe.

Is Daktronics seeing more instances of wildfire, flooding and dust storms in your deployments?

Our expertise is designing, manufacturing, installing, and supporting LED display technology. We recognize that our products – specifically ITS dynamic message signs – are exposed to extreme environmental conditions. This is why our team is so dedicated to testing quality and reliability. Using our knowledge from our on-site lab, we have substantial data to demonstrate how our products will withstand the test of time and how our products will continue to perform in the harshest environmental conditions.

Do you think ITS products help mitigate the effects of climate change? How?

Our lab services are constantly evaluating new and changing ways to test our products. This allows us to be a leader in product development which is instrumental in being ready for changing weather and conditions. ITS products continue to play an ever-increasing and critical role in enhancing the efficiency of our roadways, mitigating congestion, and improving safety; which all contribute to minimizing the impact on the environment.