Talking Shop with Daktronics Engineering

What’s it like to have an inside look at early, top secret product design ideas? Lenny Sik knows a little bit about that. He runs the product development shop in Brookings, South Dakota, where countless concepts for new Daktronics products and features go through a first round of the proof-of-concept gauntlet.

Jennifer Liebschwager on 2/22/2018

Categories: Business & Community

What’s it like to have an inside look at early, top secret product design ideas? Lenny Sik knows a little bit about that. He runs the product development shop in Brookings, South  Dakota, where countless concepts for new Daktronics products and features go through a first round of the proof-of-concept gauntlet.

Dakota, where countless concepts for new Daktronics products and features go through a first round of the proof-of-concept gauntlet.

We recently sat down with Lenny to talk about how the shop fits into product development and how the space has evolved over the years.

What role does the product development shop play in engineering innovation at Daktronics?

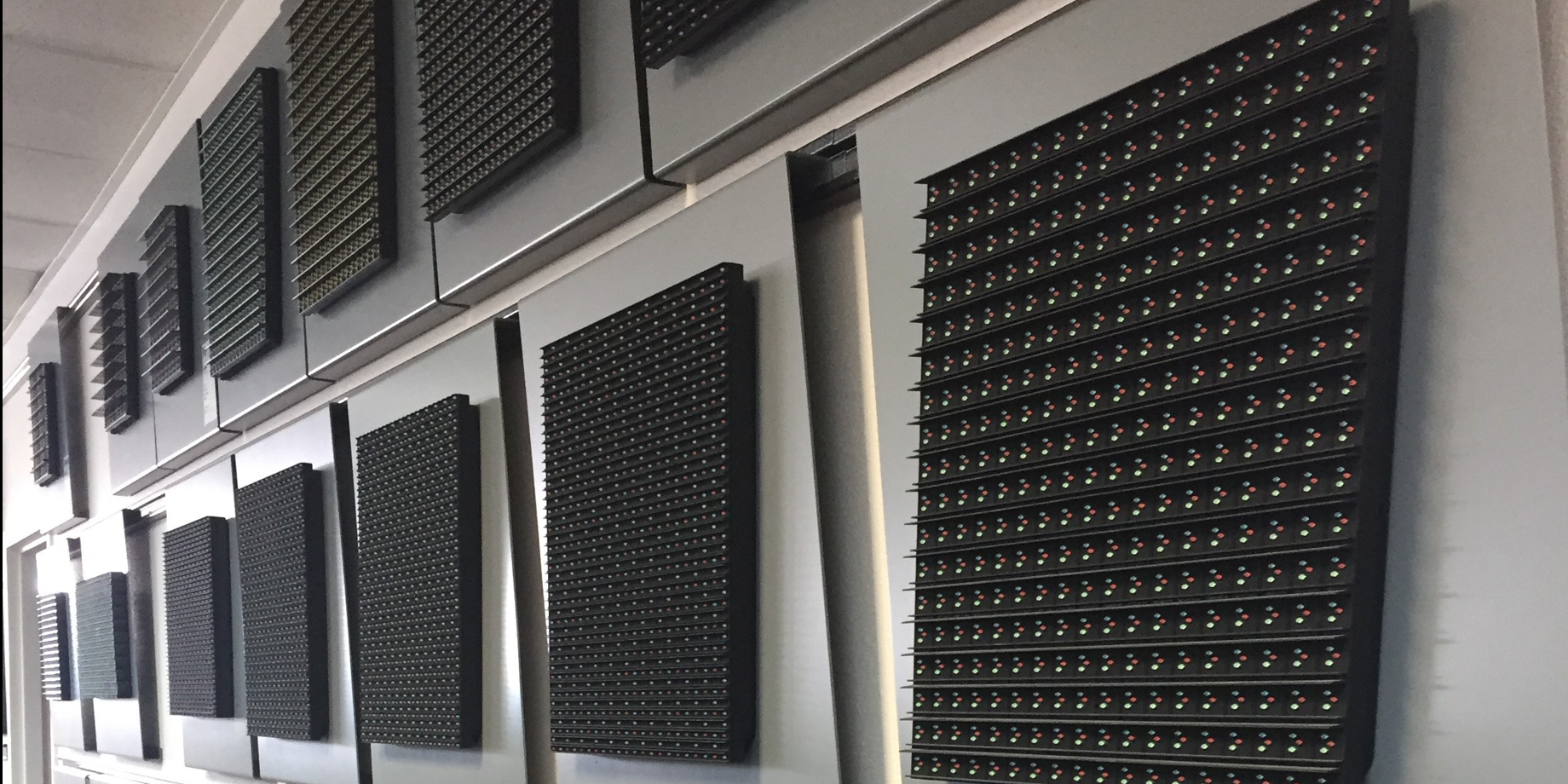

It’s a location that the engineering can come down and test out their design. We have bins of extra components and different work stations organized by what part of the product they’re working on. Engineers can come down and put a physical prototype together to test the theory of their design before they order parts or invest in materials to do a full design.

It’s also an engineering bonding location. You have the different development groups using the same area, so they can collaborate really easily and test out full design. It’s brainstorming central.

How has the shop grown from the beginning until now?

Before the shop, engineers were using conference rooms and sometimes areas on the manufacturing floor to try and build their ideas. Before I helped get the shop going, I worked on the floor in assembly for 20 years and all those years, engineers would want to mock things up but they never had a dedicated space. On the line, it’s high pressure, strict timeline to meet contracts, but I’d always try to find them a table and a drill so they could test out their idea on a solid surface.

I had one experience where I was working on a mock-up on the manufacturing floor and had to leave for a meeting. I came back, the table was gone and the tools were gone, taken away for something needed on the line, and the mock-up materials were on the floor. This was the moment that I saw what it was like firsthand and really felt engineers needed a dedicated space for working through these ideas.

We were looking at spaces we could use and it just so happened there was an shared storage area that could be re-purposed. There was no shortage of work to prepare the space, as many groups had been using it to store odds and ends from different areas throughout the company. But the engineers and I set to work. This was great timing with the Lean concepts being implemented across the company. It helped get the area cleaned and we started off the right way with an organized process. Lean is still a big part of keeping the shop clean and organized today.

Seeing the example of the shop team with the video products area, groups in Building 3 for Transportation and Sioux Falls reached out to help build similar areas in those locations.

What’s your favorite part of working in the shop?

My favorite part is helping people and providing tools to help with the development process. I also like brainstorming together with people building module and cabinet concepts. A lot of times, people will come in with a general concept and they may need to talk through some ideas to get a final design, so it’s nice to have the opportunity to collaborate. I always say that it’s a shared area. It started in video products, but anyone who wants to test out an idea is welcome in the shop.

Thanks for sitting down with us, Lenny! We look forward to seeing what new Daktronics innovation comes out of the shop next. For another inside look at product development, check out our interview with one of our video processor engineers as we celebrate National Engineers Week.