Reliability Testing: Good Looks That Last

Daktronics is committed to providing reliable, long-term image quality. That’s why the professionals of Daktronics Lab Services run components and fully completed displays through a battery of reliability testing, ensuring our displays make customers look incredible for years to come.

10/3/2024

Categories: Business & Community, High School Sports, Out of Home Advertising, Pro Sports and Colleges, Sign Company News, Spectaculars, Transportation

Daktronics Lab Services – Integrity. Quality. Reliability.

Daktronics LED video technology is well known for its reliability. Our displays turn on and look fantastic even in harsh sunlight, torrential rainstorms, severe blizzards, and oppressive humidity.

That’s because we run our products through a comprehensive series of tests in house to determine how long they maintain their image quality as they age, no matter where they are installed.

Testing for incredible digital color, even in sunlight

One crucial aspect of long-lasting good looks is standing up to sunlight and humidity. Whether a display is installed indoors or out, chances are it will be exposed to direct sunlight for years at a time, and humidity can be a factor in nearly any environment.

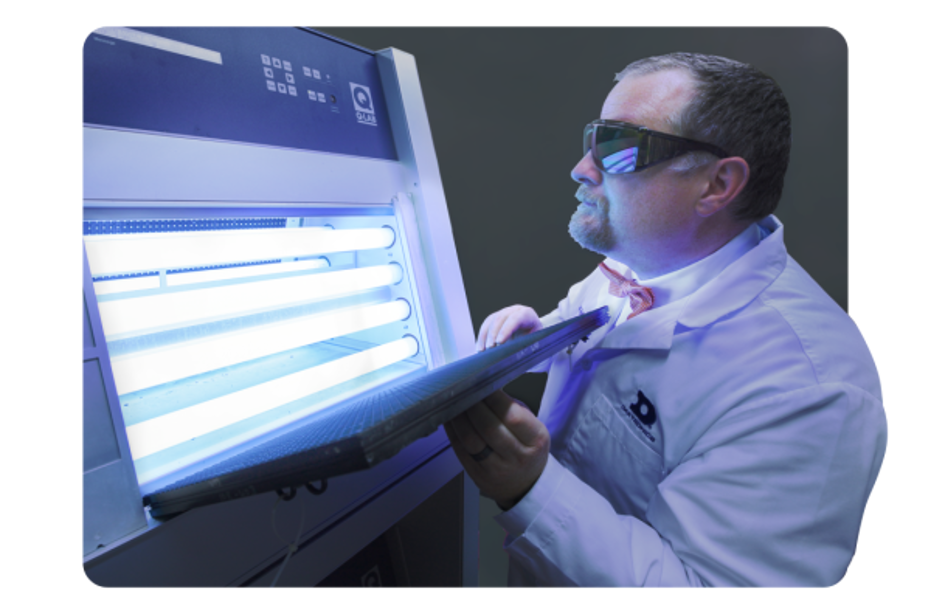

At Daktronics Lab Services, we discover those effects using the QUV accelerated weathering tester. This “tanning bed,” as we call it, helps us analyze how plastic, paint and LEDs degrade over time when exposed to ultraviolet light and condensation. By ensuring these components retain their color, we can assure customers that their content will pop after years of exposure to the elements.

LED screens with water resistance

Keeping water out of our displays keeps all those electronics working smoothly. We put our components through severe testing to prevent water permeation even under extreme conditions.

The Spray Test Chamber uses a spray hoop to simulate everything from a light drizzle to a heavy downpour, with modules withstanding water exposure from nearly every angle.

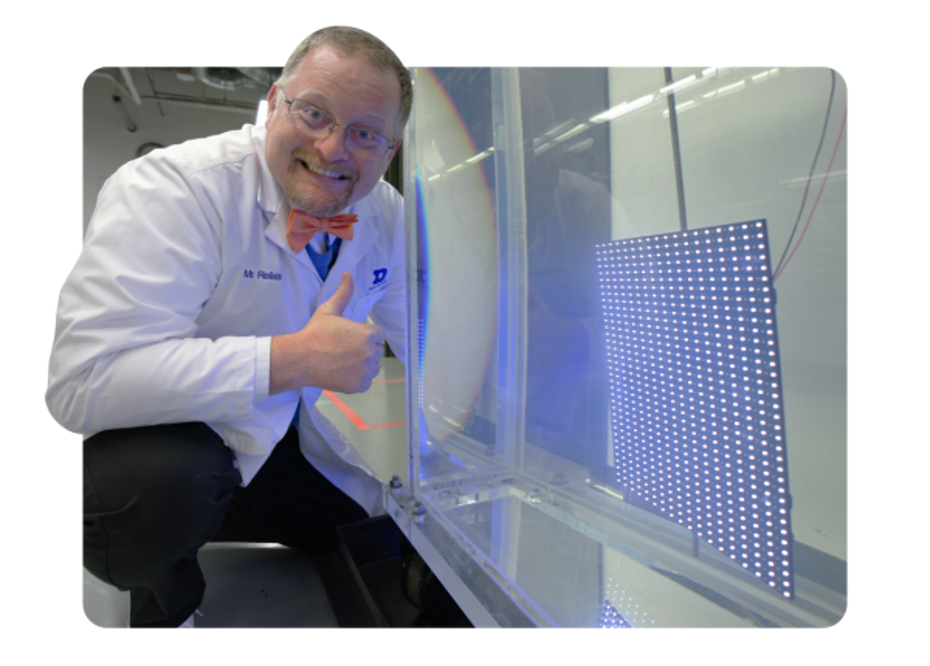

In the Water Test Booth, we see how reliably a display operates in wet and humid environments. Using a special detection powder that changes color when wet, we search for moisture inside the test subject as we apply water pressure and volume to the components.

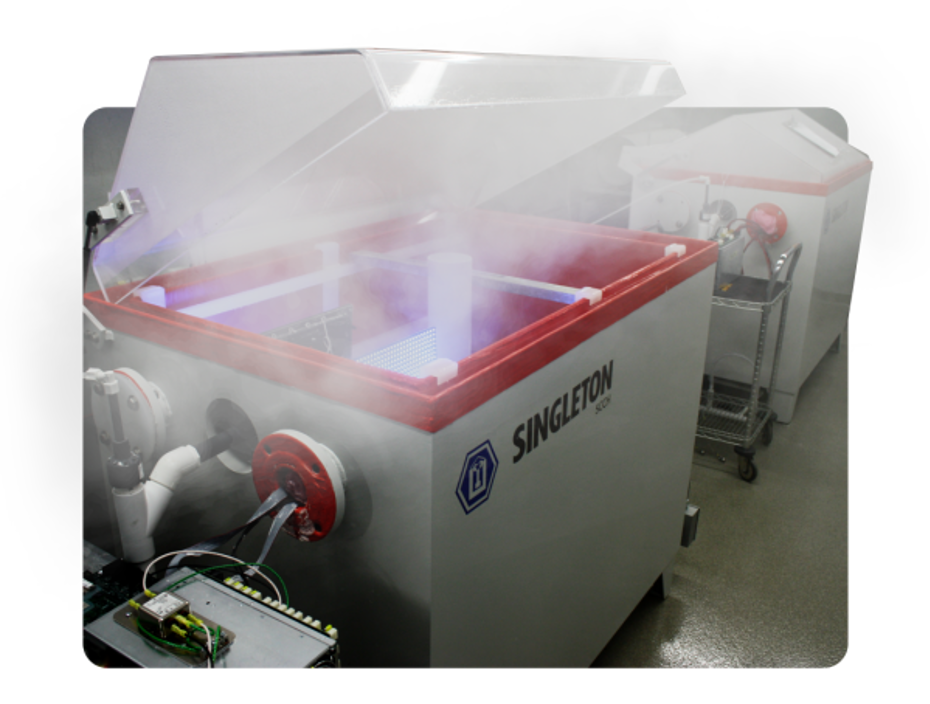

The Submersion Tank is nearly always occupied. Industry standards require that a module must operate after immersion to one meter of water for 30 minutes. We surpass those requirements by a long shot, submerging modules for 24 hours, a week, a month, or even several months. We even take it further, adding soap to our submersion tank to see how the modules react to a good washing. (Spoiler alert: They still look incredible.)

Finally, the Salt Fog Chamber tests the corrosive effects of harsh coastal conditions. We place components directly into heat, humidity and salty precipitation to gauge how electronics and coatings stand up over time.

Discover how Daktronics Lab Services test components to ensure long-lasting reliability.