Integrity Testing Matters

We expose components to harsh conditions to gauge the integrity of product performance characteristics like optical properties, power usage, efficiency and more.

7/10/2024

Categories: Business & Community, High School Sports, Out of Home Advertising, Pro Sports and Colleges, Spectaculars, Transportation

Daktronics Lab Services - Integrity. Quality. Reliability.

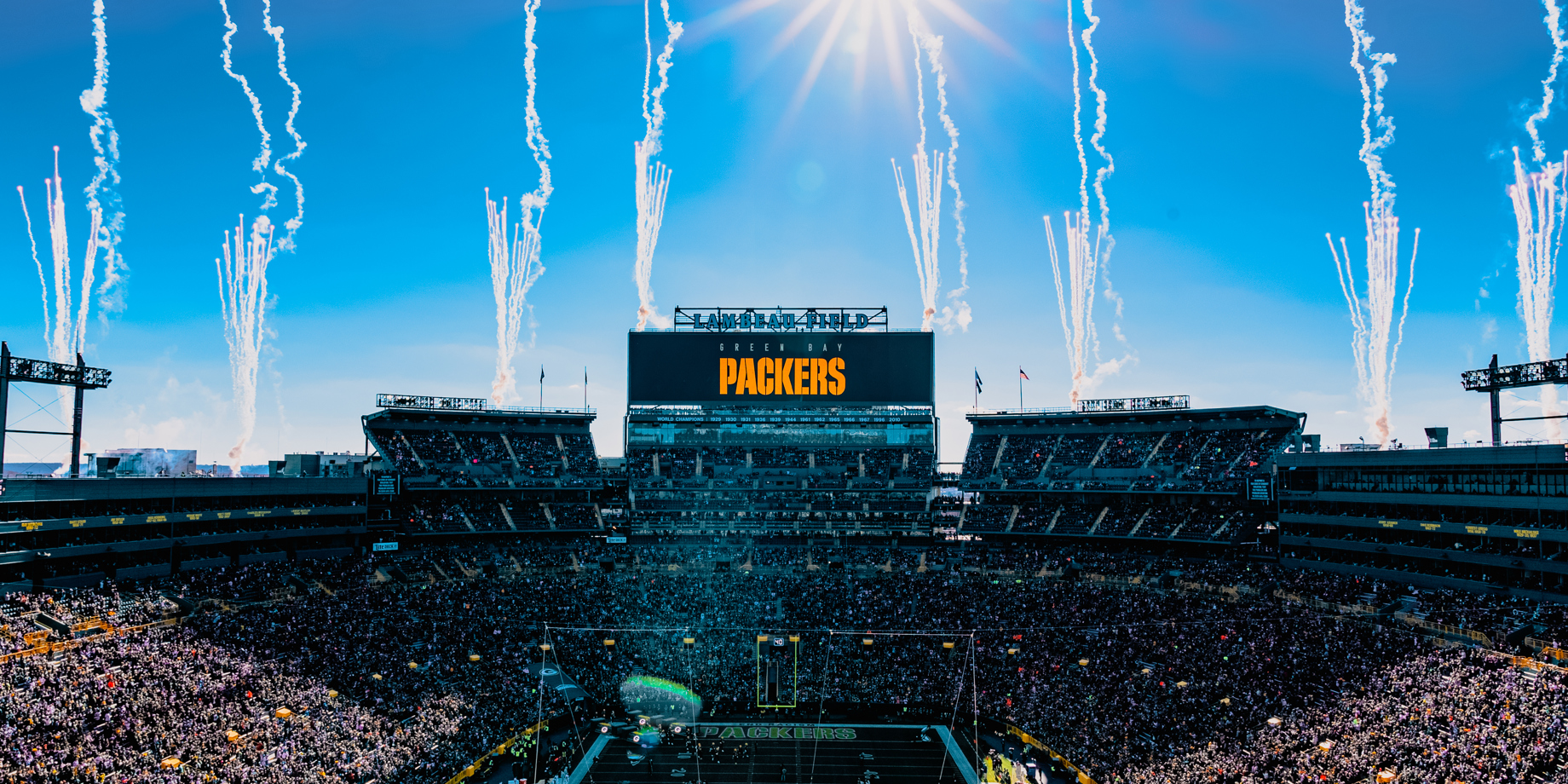

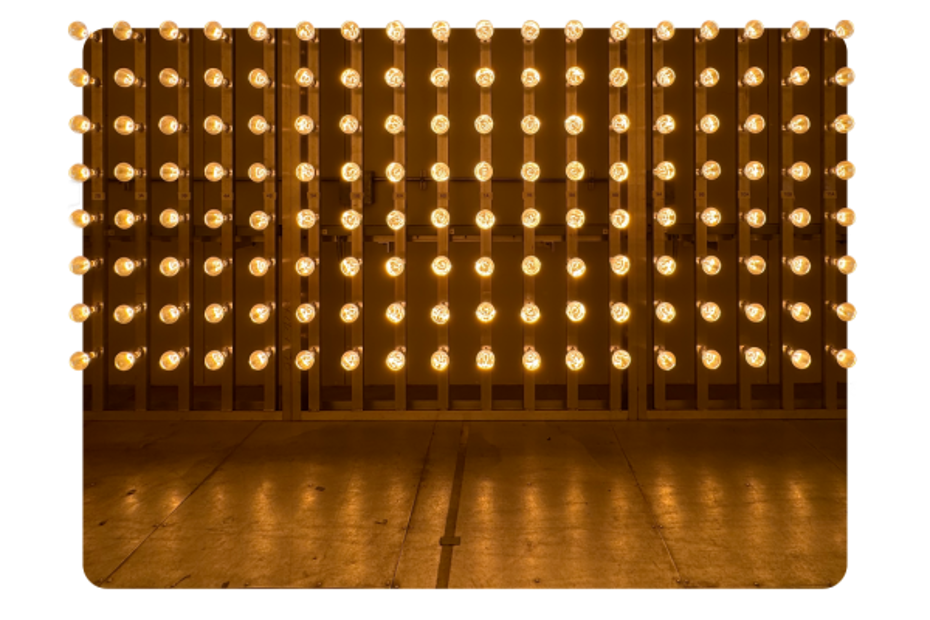

The integrity of Daktronics digital technology is one of the key aspects of the testing process at Daktronics Lab Services – our very own in-house testing facility. We make sure our displays take on simulated real-world conditions before they go out into the world, ensuring that they look great for years while surpassing compliance and safety regulations.

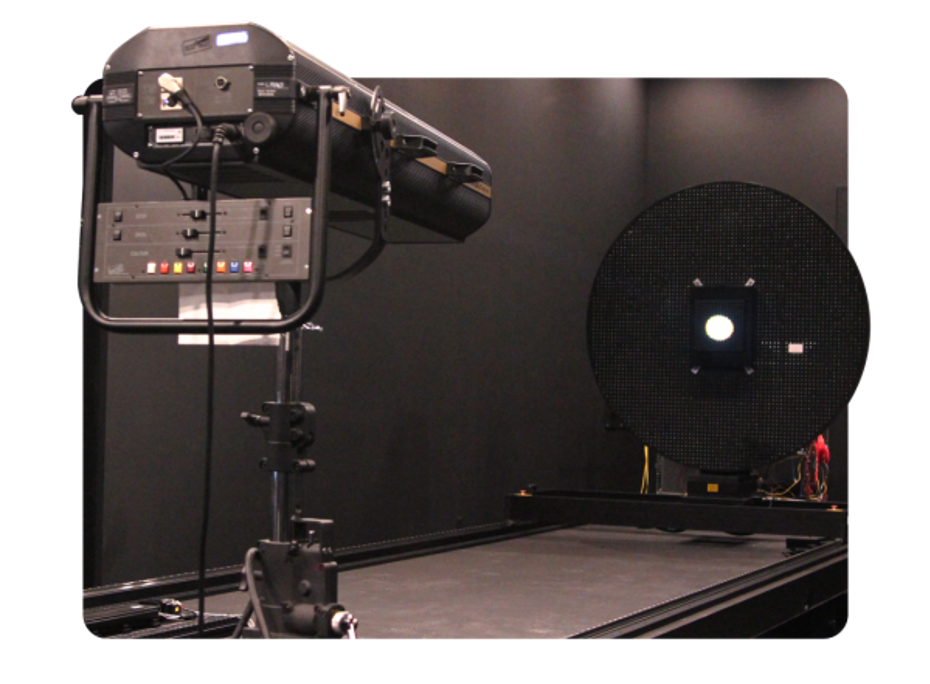

The Image Quality Lab is where we measure visual properties like luminance, maximum viewing angle, color gamut, contrast ratio and uniformity.

Basically, we make sure every pixel has amazing contrast in all lighting situations, from direct sunlight to fluorescent overhead lighting to the blackest night – so every image and message looks incredible on our displays.

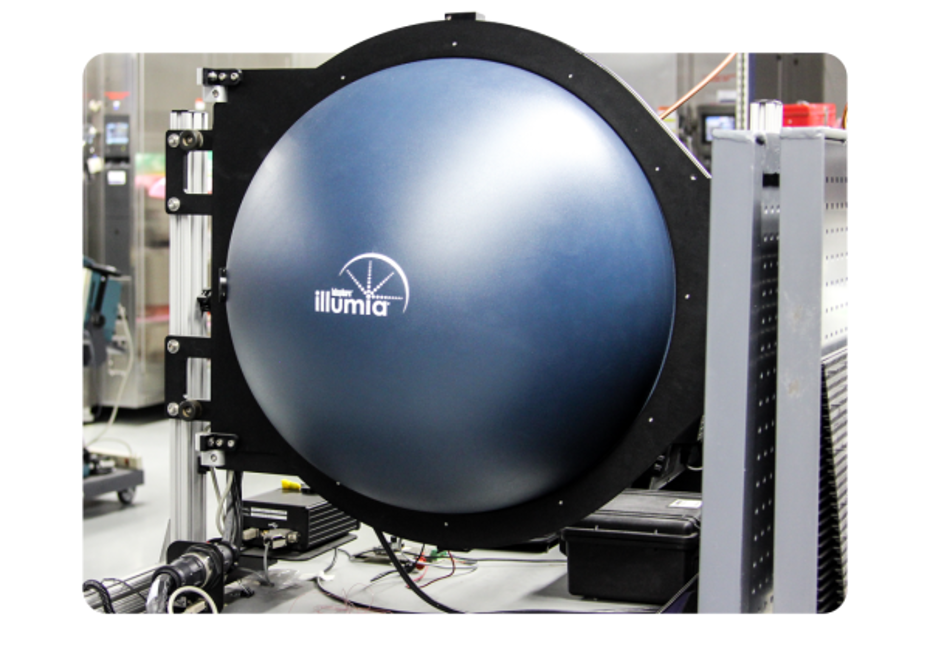

This space-age looking piece of equipment is the Integrating Sphere, which examines the luminous flux and color properties of individual LED samples. We look at display modules from different vantage points to understand what every display looks like from all angles.

We search for inconsistencies that might detract from the content our customers put on our displays – because that’s what it’s all about.

This is also where we make sure our LEDs can display EVERY color, and that the color is uniform. When the situation warrants it, we can even determine how to block light in specific directions so our customers can maintain good relationships with their neighbors.

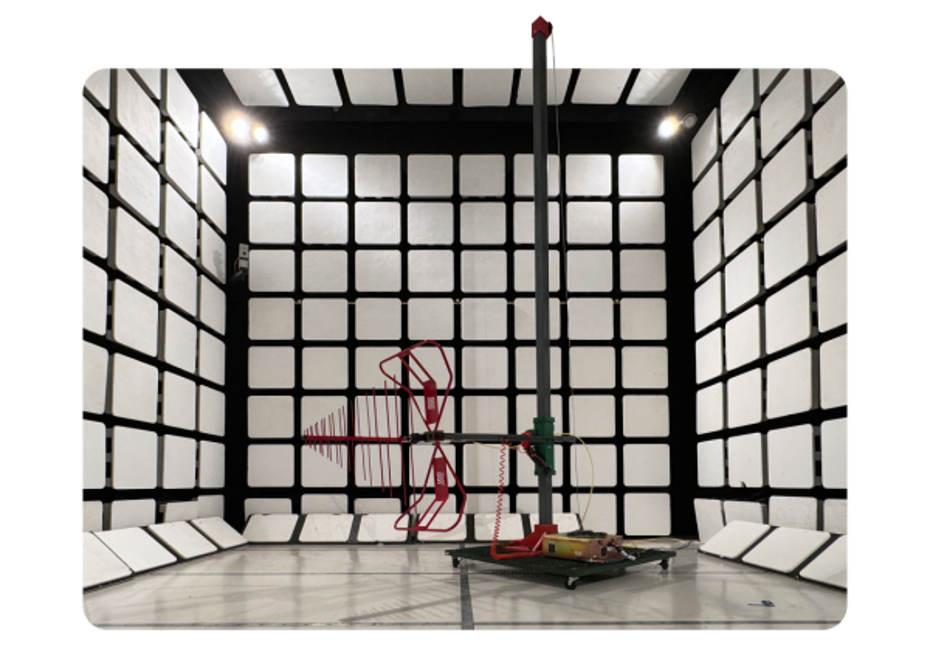

In the Electromagnetic Chamber, or EMC we check for electromagnetic radiation to ensure our products won’t interfere with other electronics like police radios, cellular antennas and Wi-Fi.

Yes, the FCC sets these limits, but we also want to make sure our displays won’t interfere with all the electronics in the world today, so we keep our emissions very low, testing the equipment 360 degrees as well as up and down.

We’ve performed these critical tests in house since 2009, saving time and re-engineering efforts because we can make quick design changes on new or custom products.

Our products need to perform their best in the most extreme conditions – in the arid desert, in unpredictable seaside environments, and even the winters of South Dakota. In the Environmental Test Chamber, we verify that our displays can handle all the extremes – incredible heat, tremendous cold and stifling humidity.

If you’re intrigued about how our Lab Services professionals help ensure the integrity of Daktronics product performance, discover more on our website.